"Threadless Corner -- The 732"

by Ray Klingensmith

Reprinted from "INSULATORS - Crown Jewels of the Wire", May 1978, page 6

The CD 732 unembossed threadless has held a special appeal to me for some

time. In purchasing my first jewel of this CD# three years ago, I was totally

unaware of all the variations and interesting facts concerning this item. I

guess the most noticeable factors were color and size variations. Let's cover

the size variations first.

The most often encountered size seems to be the 4

inch (approximate) tall ones. This size is found in various colors. Next we

have the 3-3/4 inch variation. These seem scarcer, and all I've seen were of a

light lime-mint green color. After this we have a few "odd ball"

sizes. I have seen a beautiful jade green item measuring 4-1/16 inches tall. The

tallest unembossed "732" I've run across is a monster 4-7/16 inches

tall, which is a "ginger ale" color. The first impression of these

varying sizes would lead one to believe they were made in different molds. But

they weren't! Every unembossed CD 732 of the 3-piece button mold variety I've

seen came from the same mold.

You may wonder how I can make this claim. In

looking these jewels over closely, I noticed they all had one thing in common:

they had a series of lines running in the same patterns (see drawings), especially noticeable on the dome. Why these "lines" appear on the

insulators is a mystery. These lines are not recessed, but stand out from the

body of the insulator just a fraction of an inch. Also, in the wire groove (see

fig. 1) can be found a small projecting piece of glass. This varies in size from

almost non existent to almost 3/4" long, and stands out up to 1/16"

from the wire groove.

Three varying sizes. From left to right: 4" medium green, 4- 7/16"

"ginger ale", 3- 3/4" lime-mint green. (Notice how the pinhole

extends into the dome on all three pieces - same distance from base to top of

pinhole.) |

Courtesy of Bob PierceThis is the crude and beautiful jade green, 4- 1/16" tall variant.

|

All the information so far may seem of little importance to some, but it

brings forth a few questions. First, it indicates one manufacturer supplying

vast areas with this style. I have confirmed its use in various locations of New

York, Pennsylvania, Ohio, Michigan, Georgia and Florida. It undoubtedly was used

in other states also, and was manufactured more than likely over a somewhat long

period of time in fairly large numbers. Second, it raises a question: How could

there be different sizes if all were made in the same mold? The first idea which

comes to mind, is that the shorter size was made first; then an extension was

added to the mold to gain the height for each of the taller styles. But after a

lot of study, I've come up with another idea. I think one mold was made, with

the cavity in which the glass was poured, perhaps 4-1/2" high (or higher).

Now, let's assume 14 ounces of molten glass were poured into the mold, and the

plunger inserted. The threadless pinhole, the inner portion of the skirt, and

the base of the insulator were formed in that operation. The result: a

"short" insulator. Now, assume 16 ounces of molten glass were poured

into the mold instead of 14 ounces. The result: an insulator of medium height.

Now, assume 18 ounces of glass were poured into the mold. A tall version would

be the result. (The number of ounces referred to above are just examples, as I

didn't actually weigh them.)

An interesting thing to point out at this time to help confirm the above

theory is the fact that when viewing these insulators, it's approximately

3-5/16" from the base of the insulator to the top of the pinhole. This

indicates the plunger was inserted until the pressure of it forced the molten

glass against the sides of the mold. At that time the insulator would be

completely formed. All this is hard to explain, and I hope it isn't confusing.

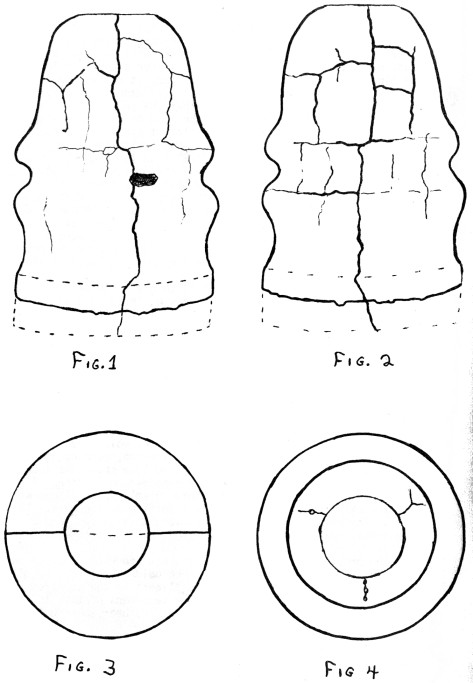

On the following page, figure 1 shows the "lines" forming a pattern

on the insulator's surface, and the "glass spot" or projection in the

wire groove. The mold lines would be to the extreme left and extreme right of

the drawing. The dotted lines show the shortest and tallest versions. Figure 2

shows the opposite side of fig. 1. Figure 3 shows the top view. The lines show

the mold lines as they come up the sides of the insulator to the flat top,

forming the so-called "three piece button mold". The dotted line shows

the location of the mold line if it were on a mold-line-over-dome version;

Figure 4 shows a base view. Notice also the three evenly spaced lines which run

from the entrance of the pinhole to a point near the base. These are similar in

characteristics to those found in figures 1 and 2. They are evenly spaced, which

indicates they represent some use in manufacture.

All the previous information covers the unembossed "3 piece button

mold" variety. There also is a 2 piece mold item (mlod, or

mold-line-over-dome). This does not have the "lines" on the surface,

as it came from a different mold. Of the few specimens of this type I've viewed,

all but one were of a beautiful rootbeer amber color. One was a blackglass

green.

I should make note that I have not included the embossed CD 732's in this

article, as they will be included in a future listing.

So far I have seen or have had reported to me five different height

variations and several different colors. The colors are: jade green,

"ginger ale", true medium green, light lime-mint green, aqua, green

aqua, green aqua full of milky streaks, light blue with milky streaks,

and jade green full of milk. These are of the 3 piece button mold. The two piece

mold comes in rootbeer amber and blackglass green. I may note the following

descriptions of colors used above: Ginger ale-This is the color of ginger ale in

a clear glass, only a darker shade. True medium green - The color of the common

"green" crayon. Light lime-mint is about the color of a candy mint.

As far as the manufacturer of these is concerned, we have no positive

information. The widespread use of these suggests a manufacturer well known in

the field. This style was in later years produced (threaded units) by both

Brookfield and Hemingray. Hemingray made use of the 3 piece button mold on the

threaded units, which indicates one possible source of those; but that doesn't

make any positive ties. So, at the present, their manufacturer is unknown.

In conclusion, may I suggest this could possibly create one of the largest

potential collections of one style in threadless, considering all the color and

size possibilities. Most of the 732's seem to fit into the 4" tall class.

This indicates the glass was carefully measured. Different times of manufacture

may be responsible for the height variations, as each could have been carefully

measured. Let's hope whatever they used to measure the amount of glass with,

didn't come in very many size capacities, or we could end up with an endless

amount of different heights, and it would be hard to distinguish where one

height started and left off. I might also add that the lines are not always

clearly visible on the surface, due to the "whittled" effect or wavy

surface caused from temperature changes and manufacturing techniques. The

"lines" are there. Look real hard!

If anyone has any variations to report, or if anyone other than myself has

taken on the project of trying to build a large collection of these, please let

me hear from you. My address is: 709 Rt. 322, Fast Orwell, Ohio 44034.

For their help in confirming variations on these items, a big thanks goes out

to Bob Pierce, Dick Bowman and Fred Griffin.

Next month (hopefully) the item in "Threadless Corner" will be the

NY&ERR.

"Update"

I no sooner opened the mailbox and found my February issue of Crown Jewels,

which featured the "Bennington" threadless, when I learned of the

second known specimen of this rare and beautiful threadless. Seems as though an

individual from Massachusetts ran across the jewel in his home state. Although I

don't have all the details on this item, I believe it was used on one of the

early lines between New York City and Boston, Massachusetts, because of its

being found in the location of one of those lines.

|